Your Drilling Equipment & Service Partner!

PRODUCTS & SERVICES

Setting Records For Deep Hole Drilling In The Mining Industry

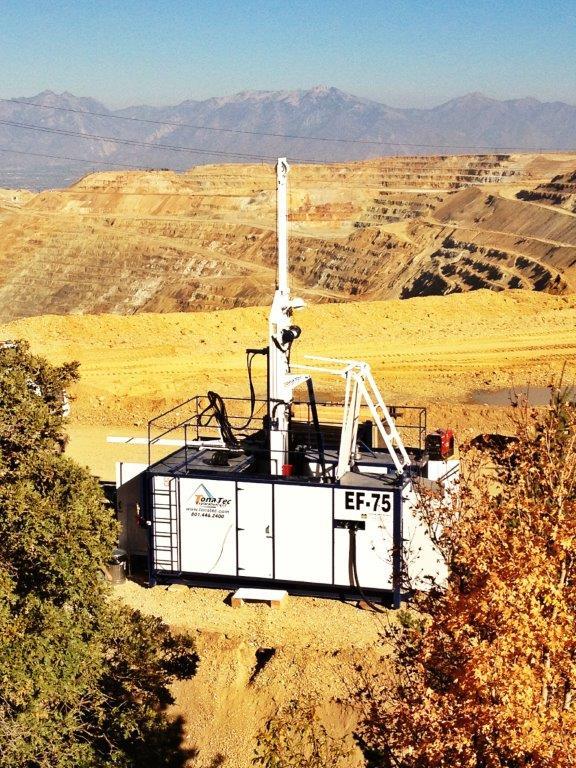

We take pride in having set industry records with our EF-100 model which has achieved the deepest hole ever drilled, solidifying our reputation for innovation and performance.

This advanced series also includes the EF-50 and EF-75 models, offering versatility with skid-mounted and heli-portable configurations to tackle diverse drilling project.

Capable of drilling depths ranging from 5,000 feet (1,524 meters) to 7,000 feet (2,134 meters) using N-size rods , the EF Series is engineered to excel in even the most challenging environments.

Designed with operator safety and durability in mind, the EF Series features hydraulic leveling jacks, advanced rod handling systems compatible with B, N, H, and P rods , and a robust drill head assembly.

Optional enhancements, such as Juniper wood flooring, add to the safety and functionality of your mining operations and drill operators comfort!

Explore Our Innovative

Drilling Equipment Essentials

That Support Your Next Drilling Project

Constructed with half-inch plywood painted with high-resistance epoxy paint. The drill shack is designed with easy access to all components that require maintenance and service.

A 12-volt automotive lighting system is incorporated at key points in the drill shack to provide sufficient lighting for safety during night operations.

The flooring consists of 3-inch thick Juniper wood product for durability and safety from slipping injuries. This feature is optional with the Heli-Portable drills.

DDM also can customize a steel drill shack.

A key feature of the EF Series Drills is the hydraulic leveling jacks located in the four corners of the drill shack. The built-in jacks reduce set-up time considerably while being safe and efficient.

The jacks have a 4-foot stroke and are powered by the hydraulic system of the drill unit.

The drill can be raised by 4 feet allowing for easy loading and unloading from a transport vehicle. The jack controls are situated on the rod handler valve bank.

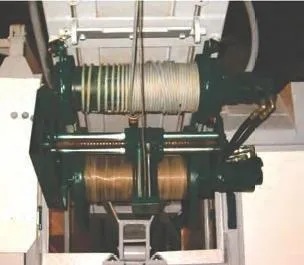

Our rod hoist has a lifting capacity of 1,000 lbs (454 kg). The drive hub is reversible which reduces downtime in field operations if it requires changing.

The rod hoist bearings are identical to the ones used in the wireline hoist, the pulleys, and drill head thus reducing the need to carry a large array of replacement parts.

Securing The Future In Mining With Our TURNKEY DRILL RIGS

Our Skid Mounted and Heli-Portable Drills have a complete drill head assembly which includes the chuck, transmission and rotation motor.

The drill head is designed with efficiency and strength in mind to provide the necessary power to drill down to 5,000 feet (1,524 m) N for the EF-50 and the EF-50F, and 7,000 feet (2,134 m) N for the EF-75 and the EF-75F.

Driven with a sprocket drive at a 2.14:1 ratio with a 50-6 drive chain. The rotation motor is a fully variable 160cc (cubic centimeter) to provide the highest efficiency at the desired bit RPM with a capability of using B-N-H rods.

An optional P size head assembly is available for P size rods. The transmission is a 4-speed Funk with a first gear ratio of 6:1 and a 1:1 fourth gear ratio.

DDM also can customize a steel drill shack.

Our Rod Handler is a fully hydraulic drill with B-N-H-P rod capability. This efficient rod handler has controls that are clearly identified for easy operation by the drilling helper. The rod handling system is fully designed to provide the drilling operators a fast and efficient method of manipulating drill rods while tripping in and out of the drill hole during the bit changing process.

All functions during this task are performed by the drilling operator inside the drill shack; sheltered from the environment. This rod handler eliminates the need for a drilling assistant to be stationed up the drill mast, which can be 20 feet from the ground surface.

It should be noted that B-N-H-P rods can be handled with our rod handler without any required changes made to our clamp jaw. The rod operator valve bank is equipped with a shut off valve for safety when not in use.

The Skid Mounted and Heli-Portable Drills feature a complete instrumentation panel allowing for ease of operation. All the controls provide clear indicators to provide a fast and safe drilling for the drill operators.

A full array of gauges is provided to indicate the various in-hole drilling conditions. All the electrical switches and warning lights provide the operator with information related to proper operation of the drill.

The EF Series Drills are equipped with either a 6 cylinder (215 HP) or a 4 cylinder (160 HP) Cummins Tier 3 engine. The unit is designed to run at 1,700/1,900 RPM in order to benefit from its peak torque while minimizing fuel consumption.

Other engines with equal horsepower are available to customize your drill such as Caterpillar or John Deere.

Our FMC W1122BCD water pressure pump has a capacity of 37 @ 1,000 psi (140 LPM @ 69 bar). It is driven by a 18.7-cubic inch hydraulic motor.

We also provide larger displacement motors to customize your drilling project.

Our water tub is made out of a translucent heavy plastic with a capacity of approximately 200 gallons (910 litres). It is equipped with a hydraulically driven mud mixer.

A bottom drain is also provided to assure complete drainage when required.

Being a leader in manufacturer of Hydraulic Diamond Drills, DDM developed a mast raise system that exceeds the performance, efficiency and safety of any other manufacturer’s product.

Our mast raise system is fully hydraulic and operates by means of a feed screw system. The hydraulic motor that operates the feed screw is equipped with a brake to maintain stability throughout the drilling operation. The result is a drill mast that does not require any stay legs, considerably reducing setup time while being very efficient and safe.

The hydraulic system designed by DDM and uses 3 Bosch Rexroth pumps. The system is designed to run with enough flow and pressure at 1,700/1,900 RPM to efficiently perform to a depth of 5,000 feet (1,524 m) N for the EF-50 and the EF-50F and 7,000 feet (2,134 m) N for the EF-75 and the EF-75F.

Pump 1 is a closed loop system that operates the rotation functions of the drill.

Pump 2 is a pressure-compensated load-sensed 95cc pump. This pump provides

the hydraulic power to the fast-travel, water pressure pump and wireline hoist.

Pump 3 is a 28cc pressure-compensated pump that supplies power to the chuck, clamp, rod handler and all other hydraulic accessories.

This assembly has proven to be a very efficient hydraulic system.

OUR DRILLING PRODUCTS AND SERVICES FOR YOUR PRECISION DRILLING PROJECT

Employee safety is the top priority on any job site. In the core drilling industry, there are many risks to the safety of the drill operators. DDM has taken this issue to heart when designing the EF Series.

The EF Series has been designed with the operator in mind both from a safety and ergonomic perspective. All controls are driller friendly and easy to read – they include a camera and monitor that enables the operator to safely view the wireline hoist operations directly from his station.

The rod handler is fully hydraulic and is controlled from the safety and comfort of the climate-controlled drill shack. The drilling helper is not required to be stationed on the drill mast - that can be over 20 feet high. Our rod handling system eliminates the need for manual lifting, greatly reducing the chance of injury.

ON-SITE TRAINING

Our on-site training specialist is available to train employees in class or in the field. Training focuses on the proper operation of the drill units as well as their maintenance procedures. Our training specialist is not only a great teacher, he is highly involved in the design and manufacturing process of our products. He know the ins and outs of all our products.

Training is available in English, French, or Spanish.

FOLLOW US